Installation kits options 810358-5005S

This option is applicable to the following vehicles:

Referencia Modelo CC Potencia Referencia OEM

- 810358-5005S CX5 2WD 2L 148CV SH0113700E

- 810358-5005S CX5 4WD 2L 173CV SH0113700E

New versions of installation games have been introduced for the previous turbos:

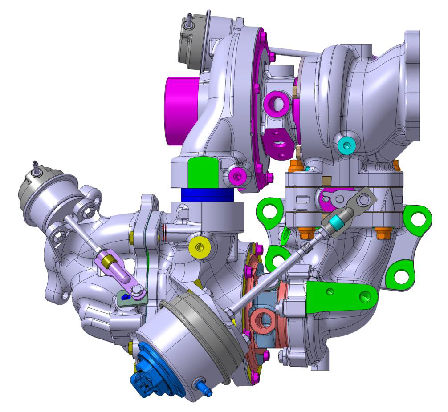

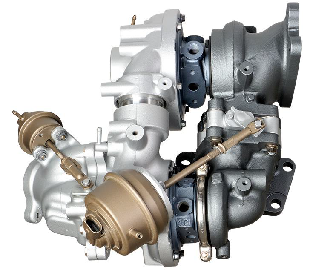

- 810358-5005S – Fully assembled 2 Stage turbochargers.

- 810356-5001S – HP Turbocharger – Model GT1238Z (bottom turbo)

- 810357-5003S – LP Turbocharger – Model GT1752S (top turbo)

- 906760-5001S – HP Turbocharger with Turbine bypass valve, actuator, studs, nuts and gaskets

- 898981-5001S – Turbine bypass valve kit (with studs, nuts and gaskets)

- 898982-5001S – Compressor bypass valve kit with actuator, bolts and gasket)

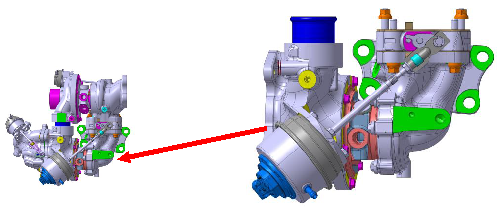

810356-5001S -HP Turbocharger GT1238Z (bottom turbo)

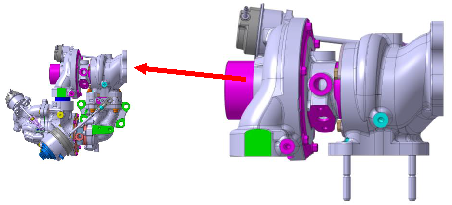

810357-5003S – LP Turbocharger GT1752S (top turbo)

906760-5001S – HP Turbocharger with Turbine bypass valve (bottom turbo)

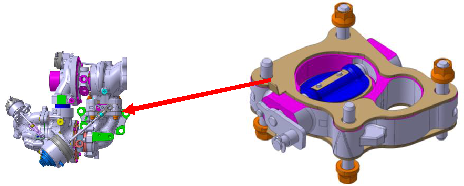

898981-5001S – Turbine bypass valve kit

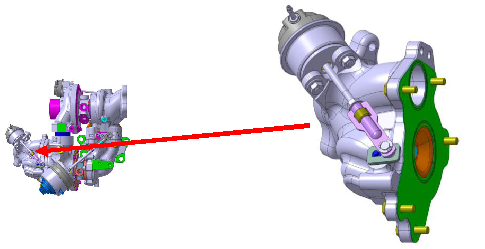

898982-5001S – Compressor bypass valve kit

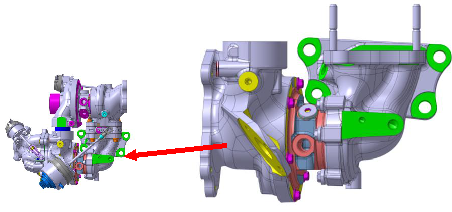

TURBINE BYPASS VALVE ACTUATOR CALIBRATION PROCEDURE

- Actuator to be re-used from original turbocharger Rod-end length setup

Go to mechanical hard stop (valve closed) by applying vacuum 600 ± 5 mBar and set stroke to 0 = to Fully Closed Hard stop – mechanical hard stop when bypass valve is fully closed

o Apply vacuum 372 ± 5 mBar and adjust rod end to set stroke to 0.5 ± 0.1 mm

o Apply torque on Rod-end nut (5.6 – 6.8 Nm)

Rod-end length re-checking

o Apply vacuum 600 ± 5 mBar again and reduce vacuum till stroke is 0.5 ± 0.1 mm

o Confirm vacuum is 372 ± 10 mBar

Turbine bypass valve nuts

- Tighten to 20.0 – 25.0 Nm of torque

Apply lubricant P-80 Emulsion or equivalent to cold decoupler prior to assembling

Compressor bypass valve bolts

- Tighten to 8.0 – 10.0 Nm of torque

Apply Loctite 271 or equivalent onto thread prior to final torque

Actuator nuts

- tighten to 5.6 – 6.8 Nm of torque